- 0531-87887788

來源:http://m.kangyanghua.com/ 發(fā)布時間:2020-01-19

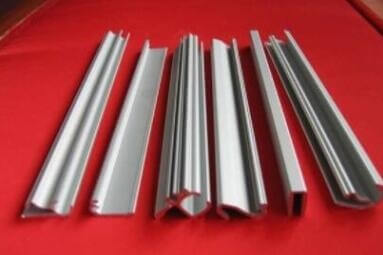

有時我們會發(fā)現(xiàn)鋁板的表面會出現(xiàn)一些缺陷,影響我們的使用和美觀,這是什么原因呢?接下來,鋁板生產(chǎn)廠家對鋁板表面缺陷的原因分析如下:

Sometimes we will find some defects on the surface of aluminum plate, which will affect our use and beauty. What's the reason? Next, the aluminum plate manufacturer analyzes the reasons for the surface defects of aluminum plate as follows:

1、折(折)輥的形狀不正確,如壓光機(jī)軸承發(fā)熱,使輥兩端膨脹,壓板結(jié)果在中間厚薄兩邊;平板的波量過大,使光量過大,造成壓縮;板經(jīng)過壓光后,很容易折疊。板的兩側(cè)厚度大,容易產(chǎn)生壓折。

1. The shape of the folding (folding) roller is not correct. For example, the bearing of the calender heats up, which makes the two ends of the roller expand, and the pressing plate results in the middle thick and thin sides; the wave amount of the flat plate is too large, which makes the light amount too large, causing compression; after the plate is calendered, it is easy to fold. The thickness of both sides of the plate is large, and it is easy to produce buckling.

2. 泡錠表面不平,有污物,裝前未清洗干凈;蝕刻后鑄塊和鋁復(fù)合板表面有蝕刻和水洗的殘留痕跡;加熱時間過長或溫度過高,鑄塊表面氧化。

2. The surface of foam ingot is uneven and dirty, which was not cleaned before installation; after etching, there are traces of etching and water washing on the surface of ingot and aluminum composite plate; if the heating time is too long or the temperature is too high, the surface of ingot will be oxidized.

3.鑄坯熱軋時,壓力過大,錠端開裂;鑄件塊受熱過高或過低。

3. When the billet is hot rolled, the pressure is too high and the ingot end cracks; the heating of the casting block is too high or too low.

以上是各鋁板生產(chǎn)廠家?guī)淼匿X板表面缺陷分析,希望對您有所幫助!

The above is the surface defect analysis of aluminum plate brought by aluminum plate manufacturers, hope to help you!